Modified epoxy acrylate UV resin for wood and paper

Standard bisphenol A epoxy acrylate with fast curing speed and good pigment wettability is used in the field of ink and adhesive with strict VOC content

Product Detail

| Product code | ZC8801A |

| Appearance | Water white or yellowish transparent liquid |

| Viscosity | 40000 -85000 at 25 Celsius Degree |

| Functional | 2 |

| Product features | Flexibility, adhesion, water resistance, good leveling and yellowing resistance |

| Application | Wood, paper, plastic coating, ink, adhesive, vacuum electroplating primer |

| Specification | 20KG 25KG 200KG |

| Acid value (mgKOH/g) | <5 |

| Transport Package | Barrel |

| Product code | ZC8860T |

| Appearance | Water white or yellowish viscous transparent liquid |

| Viscosity | 20000 -48000 at 25 Celsius Degree |

| Functional | 2 |

| Product features | Good reactivity, fast curing speed and good wettability of pigment |

| Application | Inks, coatings and adhesives with strict VOC content |

| Specification | 20KG 200KG |

| Acid value (mgKOH/g) | ≤3 |

| Transport Package | Barrel |

Product Description

Product Code: ZC8801A

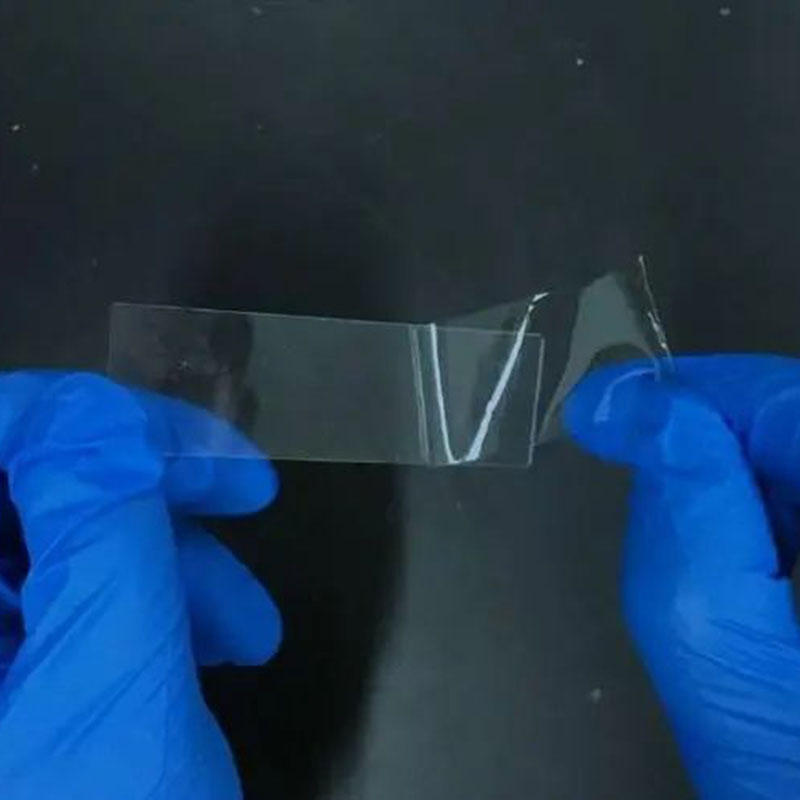

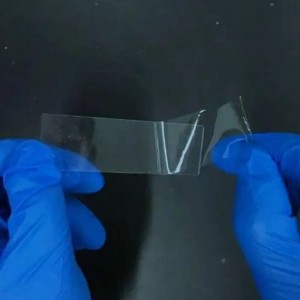

The chemical name of product ZC8801A is modified epoxy acrylate. It is a water white or yellowish transparent liquid. Customers are mainly used in nail polish glue, ink, TPU, etc. The only disadvantage is the offensive odor. It has good flexibility, adhesion, water resistance and good resistant of yellowing. Epoxy acrylate is the most widely used light curing prepolymer. In terms of structure, it can be divided into bisphenol A epoxy acrylate, phenolic epoxy acrylate, epoxy oil acrylate and modified epoxy acrylate. As a main resin, epoxy acrylate cured film has good adhesion, chemical resistance and strength, but it also has disadvantages, such as insufficient flexibility and brittleness. Therefore, in order to meet the needs of different fields, the physical and chemical modification of epoxy acrylate has become one of the research hotspots in this field.

Physical modification is to add nanoparticles to epoxy acrylate to improve the properties in the curing process; Chemical modification is to use the epoxy group or hydroxyl group in epoxy acrylate to react with the functional groups in other modified substances to prepare modified products with different properties. Polyurethane modified epoxy acrylate is mainly divided into two categories: (1) polyurethane or polyurethane acrylate is added to epoxy acrylate UV curing system through physical blending. (2) The prepolymer containing isocyanate at one end was synthesized and then reacted with epoxy acrylate. If the amount of epoxy acrylate modified by physical mixing exceeds a certain amount, phase separation will occur. In general, the flexibility of the modified epoxy acrylate film becomes better after curing.

Product 8860T is a standard bisphenol A epoxy acrylate. It is a water white or yellowish viscous transparent liquid with good reactivity, fast curing speed, hard curing film and good pigment wettability. It is a benzene free substance and meets the requirements of VOC limit index of cigarette pack. It is mainly used for inks, coatings and adhesives with strict VOC content restrictions.

Storage Conditions

Please keep cool or dry place, and avoid sun and heat;Storage temperature does not exceed 40 ºC, storage conditions under normal conditions for at least 6 months.

Use Matters

Avoid touching the skin and clothing, wear protective gloves when handling;

Leak with a cloth when the leak, clean with esters or ketones for details, please refer to the Material Safety Instructions (MSDS);

Each batch of goods to be tested before they can be put into production

Application and Product images